Feature

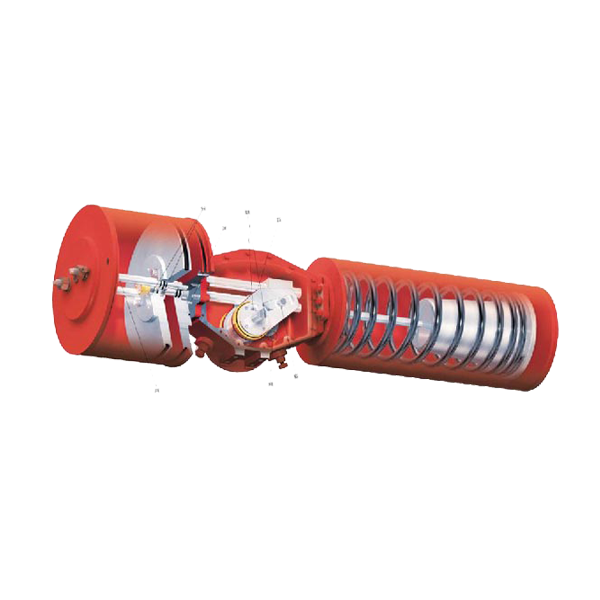

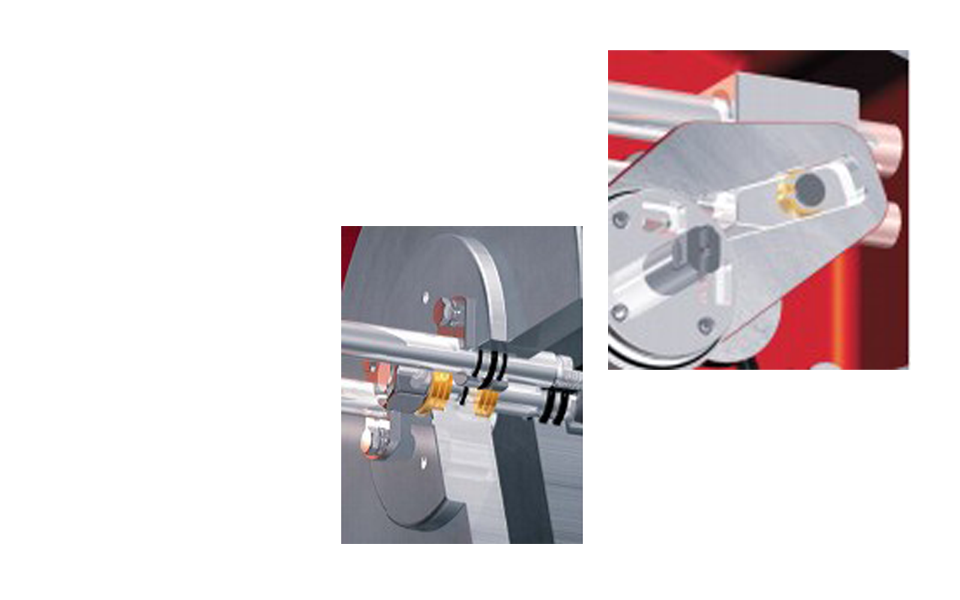

Simple actuator mounting:

The RDH2 Series actuator yoke is designed with two full – length keyways. This not only simplifies assembly but also allows for ease of modification to the actuator orientation to accommodate last minute pipe work changes, in addition to providing easier visual confirmation of alignment thus reducing maintenance and assembly time.

Piston Protection

The RDH2Series actuator has two thrust bearings on either side of the piston to prevent lateral deflection, extending piston life and making the interchangeable modules quick and easy to install.

High Efficiency

The RDH2 Series piston rod is locked by a guide block. This is supported by a high strength guide rod fitted with a self – lubricating bearing, which ensures efficient operation and improves the transfer of energy from the power module to the valve stem.

Corrosion Resistance

RDH2Series actuators incorporate four stages of internal and external corrosion resistance coating to resist severe weather, chemical and petroleum environments. The actuator exhibits excellent corrosion resistance, and has passed a Salt Spray Test to ASTMB117, making the actuators ideal for severe service duties such as offshore and marine applications.

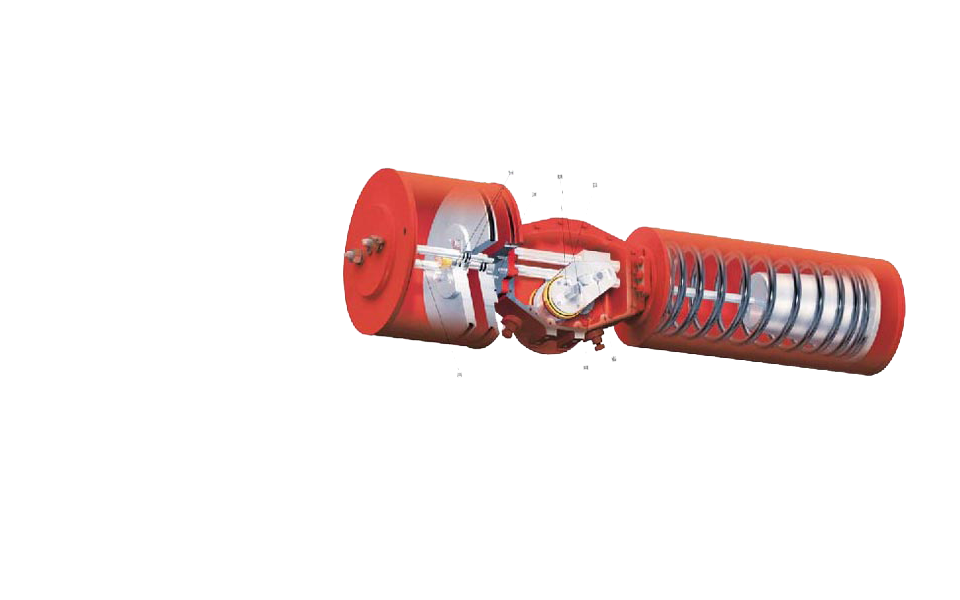

Internal Tie Rods

The RDH2 Series power module has two built – in, high strength alloy steel tie rods. These help to guide the piston, reducing internal friction. By positioning the tie rods inside the cylinder housing they are protected from corrosion and physical damage thus extending the life of the tie rod seal. The internal tie rods also remove the problems associated with the painting of cylinders featuring external rods.

WATSTM Wide Adjustable Stopper

The RDH2 Series offers an extended range of travel adjustment by utilizing a unique, patented yoke design. The yoke design, combined with two optional limit stop bolts in front of the drive module, allows travel to be adjusted from -25 to +5 degrees. If greater travel adjustment is required an stroke adjuster can be fitted to extend the available range.