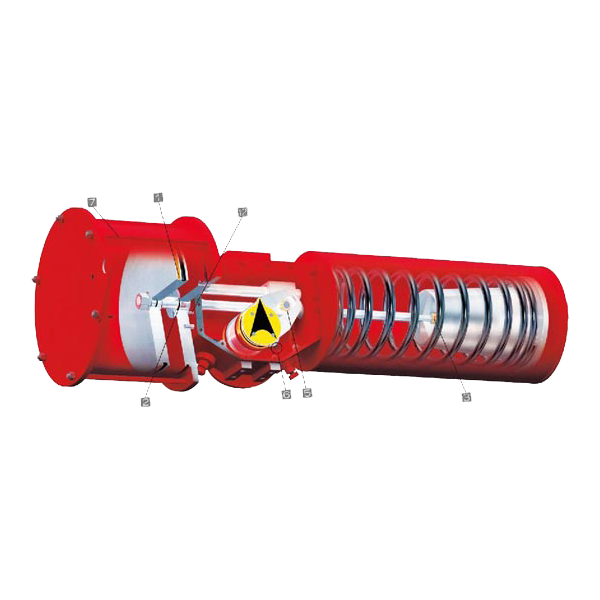

Feature

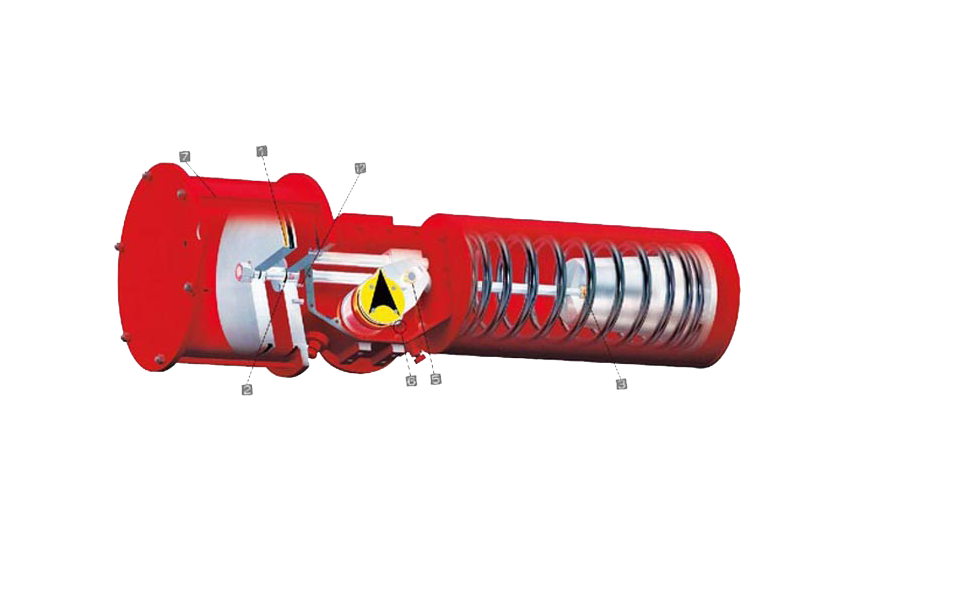

Piston Guide Ring

The RDH1-type actuator has a guide ring fitted to the piston to prevent lateral deflection, ensure smooth, steady operation and extend piston。

Advanced Sealing Compounds

The RDH1-type actuator utilizes both PTFE and rubber seals. The PTFE seal offers a high level of sealing performance and is self lubricating, ensuring smooth operation of moving parts. The rubber seal offers long term, high performance sealing with no tendency to set or creep.

Spring Rod Nut

The spring rod nut locks the spring to prevent accidental release under repetitive spring impacts.

Simple Actuator Mounting

The RDH1-type actuator yoke is designed with two full-length keyways. This not only simplifies assembly but also allows for ease of modification to the actuator orientation to accommodate last minute pipe work changes, in addition to providing easier visual confirmation of alignment, thus reducing maintenance and assembly time.

Replaceable Bearing

Low friction, permanently lubricated, high performance bearings protect all components, extending actuator life by ensuring smooth operation.

Bearing replacement is simple and instructions can be found in the operating & maintenance manual.

WATSTM Wide Adjustable Stopper

In order to set the actuator travel to give an accurate valve open/close point, two adjustable travel bolts are installed in front of the drive module. The unique shape of the yoke arm gives right-angled contact between bolt and yoke preventing deflection or damage. This unique design extends the adjustable range from -25 to +5 degrees.