Feature

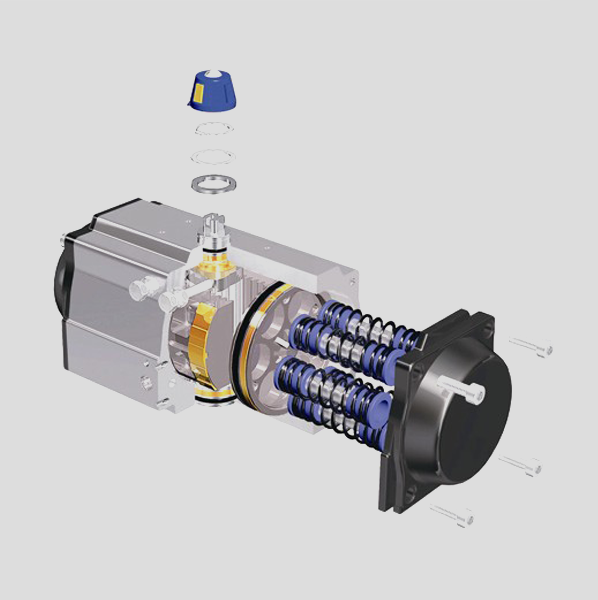

Hard Anodized Body

The extruded aluminum body incorporates an advanced, hard anodizing treatment on the internal and external surfaces. This provides reduced friction, increased durability and corrosion protection. The body can also be provided in a number of optional finishes including PTFE coated, electroless nickel plated and a variety of polyester powder coated colors.

Large Piston Design

The RDK actuators are designed with an optimally sized piston rack. This minimizes backlash between the rack and pinion ensuring that they are precisely engaged. This feature guarantees excellent power delivery and accurate valve modulation.

Advanced Rack and Pinion Design

A compact, rugged construction, with dual rack and pinion, guarantees stable torque output throughout the actuator’s travel. The design is also suitable for high-cycle, high-speed duties.

Travel Adjustment

The RDK-Series actuators provide two external travel stops allowing for ±5° adjustment in both open and closed positions. This allows accurate valve alignment and provides actuator travel adjustment from 80° to 100°. Optional bolts fitted to the end caps can provide additional travel adjustment, for the open position. The externally adjusted bolts can provide open position travel from 0 to 100°.

Piston Guide Plate

A permanently lubricated, replaceable guide plate is fitted to the piston rack to remove lateral deflection and ensure smooth operation by eliminating metal to metal contact, improving wear resistance and increasing efficiency.

Drive Shaft Bearings

The RDK-Series actuators have self-lubricating, replaceable shaft bearings providing low-friction, and high wear resistance. This enables high cycle life and reliable performance.

.png)